TOP 14 best thicknessing machines for wood: 2024-2025 ranking in terms of quality and reliability

Today's rating of the best wood thicknessing machines on our techtop.techinfus.com/zh/ portal is the best way to quickly find the right model.

For quick navigation, we have divided the rating into categories:

- The best thicknessing machines for wood in terms of price / quality ratio for 2024-2025;

- The best jointer-thickness and planer machines for wood;

- The best thicknessing machines for wood with a belt drive;

- The best thicknessing machines for wood without a bed;

- The best wood planers with two knives.

To give wooden blanks the desired thickness and smooth surface, a thicknesser machine is used.

We will tell you what to look for when choosing such equipment, and also study the rating of the best models for 2024-2025, with their technical features, advantages and disadvantages.

Rating of thicknessing machines for wood for 2024-2025

| Place | Name | Price | Rating |

|---|---|---|---|

| The best thicknessing machines for wood in terms of price / quality ratio for 2024-2025 | |||

| 1 | Makita 2012NB 1.65 kW | Ask for a price | 9.8 |

| 2 | ZUBR RS-305 2 kW | Ask for a price | 9.6 |

| 3 | PATRIOT TP 330 2 kW | Ask for a price | 9.3 |

| The best jointer-thickness and planer machines for wood | |||

| 1 | ZUBR SRF-254-1600C 1.6 kW | Ask for a price | 9.7 |

| 2 | Einhell TC-SP 204 1.5 kW | Ask for a price | 9.5 |

| 3 | BELMASH J150/1170SA 1.1 kW | Ask for a price | 9.3 |

| The best thicknessing machines for wood with a belt drive | |||

| 1 | Enkor Corvette 22-330 1.5 kW | Ask for a price | 9.4 |

| 2 | ZUBR SR-330-1800 1.8 kW | Ask for a price | 9.2 |

| 3 | Encore Corvette 21 1.5 kW | Ask for a price | 9.1 |

| The best thicknessing machines for wood without a bed | |||

| 1 | ZUBR RS-320 1.5 kW | Ask for a price | 9.8 |

| 2 | JET JWP-12 1.8 kW | Ask for a price | 9.7 |

| 3 | DeWALT DW733 1.8 kW | Ask for a price | 9.5 |

| The best wood planers with two knives | |||

| 1 | RedVerg RD-WP330 2 kW | Ask for a price | 9.8 |

| 2 | BELMASH P1800 1.8 kW | Ask for a price | 9.6 |

Content

- Rating of thicknessing machines for wood for 2024-2025

- How to choose a thicknessing machine for wood?

- The best thicknessing machines for wood in terms of price / quality ratio for 2024-2025

- The best jointer-thickness and planer machines for wood

- The best thicknessing machines for wood with a belt drive

- The best thicknessing machines for wood without a bed

- The best wood planers with two knives

- Which firm to choose?

- Useful video

How to choose a thicknessing machine for wood?

The main criteria for choosing a thicknessing machine in 2024-2025 are:

- Power. Engines with a power consumption of up to 1.6 kW can only operate in a gentle mode, with a small amount of workpieces, and need periodic rest. Models with motors from 1.6 kW are suitable for heavy loads. If you plan to work with a wide board, then it is better to choose a machine with a power rating of 2.2 kW.

- Permissible workpiece dimensions. Here you should build on the sizes of lumber available to you.

- planing depth. The planing depth limit for thicknessing machines is considered to be 2-3 mm. The depth recommended by the manufacturer reaches 1-1.5 mm, which will allow you to work efficiently with both hardwoods and wet material.

- Table dimensions. To work with meter-long workpieces, a working surface length of 500 mm or more is enough.If boards up to one and a half meters long are often used, then a machine with a table length of 771 mm would be a good option.

- The weight. This indicator will determine the possibility of installing, moving and transporting a thicknessing machine. With a weight of up to 30 kg, the device can be used on a stable table and can be easily moved if necessary. Models from 40 to 50 kg are also quite mobile, but it is better to install them on mobile or stationary stands. Machines weighing more than 60 kg are intended exclusively for stationary installation.

- Design features. The most durable are machines with steel frames and a cast base. The presence of a planer table will allow you to align the geometry of the workpiece, compression springs - to reduce the amplitude of the backlash of moving elements. Thermal protection monitors the condition of the engine and protects it from overheating. A magnetic starter will help prevent the machine from turning on after the appearance of voltage in the network.

The best thicknessing machines for wood in terms of price / quality ratio for 2024-2025

1. Makita 2012NB 1.65 kW

|

Expert assessment: ? 9.8 / 10 |

| Owner Review | |

| Well put together. Good factory settings. The tables were even (now the back table has been removed, the blanks are taken on rails). Not very noisy at work. Lightweight and compact, easy to move around. Precise scale for setting the thickness of the part. Planes cleanly enough, but there is a small step at the end of the workpiece, it is easily removed by grinding. |

One of the most popular models of thicknessing machine, which is found in almost all ratings. A good representative of a good price-quality ratio, it has a table for working with workpieces up to one and a half meters long.

The model has a solid frame body, all possible displacements are leveled due to the presence of compression springs and special steel balls located at the base of the screws.

The motor is protected by double insulation, the machine does not need to be connected to a ground loop. The automatic feed system is equipped with rollers coated with light rubber, slipping does not leave marks on the workpiece.

The device can be used immediately after purchase, as the factory setting is highly accurate. When replacing knives, it does not go astray, as well as during transportation of the machine. Great option for a small workshop.

Main characteristics:

- Length / width of the table, mm - 771/304.

- The maximum width / depth of the workpiece, mm - 304/3.

- Feed rate, m / min - 8.5.

- Power consumption, kW - 1.65.

- Number of knives, pcs - 2.

- Shaft speed, rpm - 8500.

- Machine weight, kg - 28.1.

- assembly reliability;

- low noise level during operation;

- smooth processing;

- takes hardwoods.

- no significant ones were found.

2. ZUBR RS-305 2 kW

|

Expert assessment: ? 9.6 / 10 |

| Owner Review | |

| I was looking for a thicknessing machine for personal purposes: building a gazebo in the country and various kinds of household work, you never know where else you need it. I opted for the Bison RS-305 and, in principle, did not regret the purchase. The machine is not bulky, accurate, fast and easy to use, and the boards are good. True, after some time I had to replace a couple of plastic parts, but I won’t say that this became a particular problem. |

A powerful thicknessing machine, which is part of the professional line of a popular manufacturer.

Belongs to compact portable equipment with the ability to process workpieces up to 305 mm wide, the feed rate of workpieces is 6 meters per minute. Equipped with a powerful motor with overheating protection and two high-speed cutting knives. Roller table extensions support material in and out, reducing scrap rates.

There are also rollers on the top of the machine, which makes it much easier to return the workpiece for re-planing if the desired result was not achieved during the first processing. The model has a rigid structure, there is no displacement or vibration during operation. Due to the smooth surface of the table, friction is reduced when feeding the workpiece. Also, the case is equipped with comfortable carrying handles, the weight of the device is 27.5 kg.

Main characteristics:

- Length / width of the table, mm - 307/290.

- The maximum width / depth of the workpiece, mm - 305/3.

- Feed rate, m / min - 6.

- Power consumption, kW - 2.

- Number of knives, pcs - 2.

- Shaft speed, rpm - 8000.

- Machine weight, kg - 27.5.

- high-speed steel knives;

- motor with overload protection;

- table extensions with rollers;

- good performance for a small workshop.

- no significant ones were found.

3. PATRIOT TP 330 2 kW

|

Expert assessment: ? 9.3 / 10 |

| Owner Review | |

| Chose between Jet and Bison. The choice fell on the Bison. After the purchase, I examined it, looked inside and was satisfied: the assembly is excellent, I just additionally lubricated it. Heavy, of course, for transportation, but it costs like a monolith. The tables were adjusted correctly. When planing, the chips are magnetized and clog the outlet, I had to drive back and forth with a stick when planing so that the chips do not stagnate (with minimal planing). |

A simple and easy-to-use thicknesser with a 2 kW motor, designed to process wooden blanks to the desired thickness, with a flat and smooth surface.

The design is equipped with special holes, thanks to which the device can be fixed on a support to reduce vibration during start-up and further use. Automatic workpiece feeding at a speed of 6 meters per minute helps to quickly cope with the task and is considered a good indicator for a small workshop.

The model has an emergency shutdown button located on the case in an accessible place. The engine is resistant to overloads, on the front panel there is a school for adjusting the accuracy of material processing. The machine does not require special maintenance and is suitable for long-term use.

Main characteristics:

- The maximum width / depth of the workpiece, mm - 330/3.

- Feed rate, m / min - 6.

- Power consumption, kW - 2.

- Number of knives, pcs - 2.

- Shaft speed, rpm - 8000.

- Machine weight, kg - 26 kg.

- convenient management;

- minimal noise during operation;

- sharp knives;

- easy to get consumables.

- no significant ones were found.

The best jointer-thickness and planer machines for wood

1. ZUBR SRF-254-1600C 1.6 kW

|

Expert assessment: ? 9.7 / 10 |

| Owner Review | |

| I took the machine for a garage workshop, with the understanding that it is combined, and, naturally, it will not give super quality, like machines of a higher class for a specific task (not combined). However, I have no complaints.The assembly is normal, the quality of jointing / thinning is good for my purposes - I don’t work with valuable breeds, but I think that the quality of work with them will not be perfect, but not bad. |

Combined planer-thickness machine that combines the functions of planer and planer. Suitable for use in the workshop and processing workpieces up to 254 mm wide.

Due to the belt drive, the engine does not make much noise during operation, there is overload protection. After a temporary power outage, a restart is excluded due to the installed magnetic starter. There is an automatic feed of workpieces at a speed of up to 6 meters per minute, the guiding angle of inclination is adjustable within 0-45 degrees.

The machine has two blades made of high-speed steel, which are able to process both soft and hard woods. We note the high speed of rotation of the knife shaft, which will ensure a smooth and even surface. The working tables are polished and cast, so the friction of the workpiece is reduced and facilitates their feeding. The dust collector nozzle can be easily adjusted to the desired position by the user, which helps to achieve a clean workplace and remove chips from the processed material.

Main characteristics:

- Length / width of the table, mm - 303/270.

- The maximum width / depth of the workpiece, mm - 254/3.

- Feed rate, m / min - 6.

- Power consumption, kW - 1.6.

- Number of knives, pcs - 2.

- Shaft speed, rpm - 9000.

- Machine weight, kg - 33.5.

- two machines in one at an affordable price;

- there is a chip remover;

- compact dimensions;

- included a convenient stand for machine installation;

- accuracy, ease of use.

- no significant ones were found.

2. Einhell TC-SP 204 1.5 kW

|

Expert assessment: ? 9.5 / 10 |

| Owner Review | |

| I took it for a home workshop, so to speak, for testing, in order to understand whether it was mine or not. I had to immediately adjust the height of the tables relative to each other. The blades were also adjusted immediately after installation. After the very first pine boards, chips appeared on the knife, now the stripes are visible during processing. In general, you can work, but not for super precise work. |

Stationary machine with retractable workpiece supports for fast and most accurate planing of workpieces in order to obtain the desired thickness and a smooth, even surface. There is a chip removal system, the maximum depth of the workpiece can be 3mm.

The model has an automatic material feed at a speed of 6 meters per minute. The engine power is small, 1.5 kW, so this device is not suitable for large volumes of work. However, overload protection is present.

The product is conveniently positioned thanks to the plate table made of impact-resistant aluminum and having an adjustable stop up to 45 degrees. The wide base has rubber pads that dampen the vibration that occurs during start-up. The belt-driven motor has a reduced noise level, although headphones are still recommended for comfortable operation.

Main characteristics:

- Length / width of the table, mm - 270/210.

- Maximum width / depth of the workpiece, mm - 204/3

- Feed rate, m / min - 6.

- Power consumption, kW - 1.5.

- Number of knives, pcs - 2.

- Shaft speed, rpm - 9000.

- Machine weight, kg - 24 kg.

- good assembly and factory calibration;

- there is a stop adjustment;

- rubber pads to eliminate vibration;

- light weight.

- small engine power, not suitable for professional use.

3. BELMASH J150/1170SA 1.1 kW

|

Expert assessment: ? 9.3 / 10 |

| Owner Review | |

| I started building my own private house and realized that a woodworking machine would be useful to me. Studying the market and reviews of machines, I settled on this model. In work, he showed himself quite well - a powerful motor, many functions, and especially pleased. that the machine is easily reconfigured if the need arises. But still, one minus became noticeable - the saw blade was not installed quite evenly (maybe I was just “lucky”). It is not always convenient to work without markup - it is absent. |

Planer from a Belarusian manufacturer for stationary placement, equipped with a 1.1 kW engine. Suitable for processing wood blanks in order to give them the desired size and shape. Using this machine, the user can perform the following operations: planing along the plane and edges, planing at the desired angle (along the edge), sampling a quarter.

The manufacturer performs all the main components of the machine from cast iron; receiving and falling table, parallel stop. It is possible to connect an exhaust unit for waste disposal through an aspiration nozzle. The knife shaft, which runs at 4800 rpm, has a molded protective cover. The device is placed on a prefabricated frame, and the knife shaft can be replaced with Helical or Spiral shafts.

Main characteristics:

- The maximum width / depth of the workpiece, mm - 152/3.

- The bed is portable.

- Power consumption, kW - 1.1

- Number of knives, pcs - 3.

- Shaft speed, rpm - 4800.

- Machine weight, kg - 93 kg.

- suitable for multiple operations;

- basic elements of cast iron;

- angle can be adjusted

- simple service.

- no significant ones were found.

The best thicknessing machines for wood with a belt drive

1. Enkor Corvette 22-330 1.5 kW

|

Expert assessment: ? 9.4 / 10 |

| Owner Review | |

| In general, the Corvette thicknesser is a very good car, but again, depending on what to compare with. The advantages of this machine include the width of the workpiece being processed - 330 mm and the path ejection of sawdust into a directly connected bag. But this, alas, ends the pluses - after a couple of weeks the stopper crumbled, the knives turned out to be disposable, and their replacement is quite difficult. |

Thicknessing machine for working with wood blanks up to 320 cm wide, which is equipped with an electromagnetic starter that protects against restarting after a power outage.

The anti-kickback is responsible for safe operation, the engine is protected from overheating, and the planing depth limiter with a convenient indicator will prevent overload and further damage. There is a connection for a vacuum cleaner in the form of a pipe to remove waste.

If necessary, the workpiece is returned to the receiving table thanks to the upper rollers, the automatic feed rate is 7 meters per minute and is carried out by two rubber-coated rollers, the coating of which does not leave marks on the board. Knives are sharp, double-edged and work well on both hard and soft woods and are easy to replace.

Main characteristics:

- Table length/width, mm — 330/235

- The maximum width / depth of the workpiece, mm - 330 / 2.4.

- Feed rate, m / min - 7.

- Power consumption, kW - 1.5 kW.

- Number of knives, pcs - 2.

- Shaft speed, rpm - 8500.

- Machine weight, kg - 33 kg.

- cuts well;

- optimum power for small volumes of work;

- motor with overheating protection;

- three-year manufacturer's warranty.

- you have to spend time setting it up, the factory calibration leaves much to be desired.

2. ZUBR SR-330-1800 1.8 kW

|

Expert assessment: ? 9.2 / 10 |

| Owner Review | |

| For a year with a little 12 cubic meters of wood. I started to get impudent - I stumbled the impeller and, as a result, damaged the winding. Rewound for 2000 with an impeller. Acceptable for me. Of the shortcomings are weak knives. Especially relatives. From a not very high-quality alloy - they even magnetize badly. I don’t recommend sharpening regular ones - they will quickly sag. New 2500 for 10 cubes is enough. If at the same time the model is treated carefully, there will not be many problems with it. |

Compact size thicknesser with simple operation and robust assembly. The model is portable, well suited for small and medium-sized work, it will take both hardwood and wet wood.

There is an electronic indicator, which, together with a millimeter scale, helps to control the accuracy of the processing depth and height of the thicknessing table. To adjust the depth, as well as securely fix the workpiece, the manufacturer equipped the machine with a rotary handle.

Additional advantages of the model include the presence of a convenient switch for automatic feeding of workpieces. The user can select a speed of 4 or 6 meters per minute. A dust collector can be connected to the machine, it is also possible to install a table extension with a size of 355 mm by 195 mm (length / width)

Main characteristics:

- Length / width of the table, mm - 330/285.

- The maximum width / depth of the workpiece, mm - 330/3.

- Feed rate, m/min - up to 6.

- Power consumption, kW - 1.8.

- Number of knives, pcs - 2.

- Shaft speed, rpm - 9000.

- Machine weight, kg - 40.

- the ability to connect a dust collector;

- adjustable feed rate;

- convenient management;

- does not move during operation.

- weak native knives;

- additional calibration required.

3. Encore Corvette 21 1.5 kW

|

Expert assessment: ? 9.1 / 10 |

| Owner Review | |

| In general, to sum up the impressions, they are excellent, despite the shortcomings. Of course, this is a fairly simple desktop machine, but another is not expected for such money. If you do not find fault too much, and carefully monitor the condition of the mechanisms, then it will work for a long time and without breakdowns. Now I can say with confidence that the main breakdowns were from “oversight”. |

Another machine from this manufacturer, equipped with a reliable motor with a thermal relay and a belt drive that protect the device from overheating and breakage.

The motor power is 1.5KW, this is not a professional model. Copes well with small volumes of work, designed for processing wood blanks in size in thickness. To protect against accidental activation, the device is equipped with a special key.

The machine has a depth limiter, it can reach a maximum of 2.5 mm. The feeding of blanks is automatic, its speed is 6 meters per minute. For convenience and the ability to work with workpieces of different lengths, there are front and rear folding table extensions equipped with additional rollers. The same rollers are installed on top to simplify the process of returning the board to the planing area.

Main characteristics:

- Length / width of the table, mm - 318/295.

- The maximum width / depth of the workpiece, mm - 318 / 2.5.

- Feed rate, m / min - 6.

- Power consumption, kW - 1.5.

- Number of knives, pcs - 2.

- Shaft speed, rpm - 8000.

- Machine weight, kg - 39 kg.

- two table extensions;

- reliable protection of the engine against overloads;

- key from accidental start;

- automation of the process, does not require additional settings.

- no significant ones were found.

The best thicknessing machines for wood without a bed

1. ZUBR RS-320 1.5 kW

|

Expert assessment: ? 9.8 / 10 |

| Owner Review | |

| I chose a machine in terms of price / quality ratio for personal use, and the Zubr RS-320 made me very happy in this regard. It has a strong and reliable design, the main parts are made of solid metal. The machine is also good in operation - it cuts relatively quickly, and the boards themselves turn out to be even. This is such a workhorse, maybe not the fastest, but hardy - just right for a home workshop. I recommend! |

A model that refers to portable machines for working with hard and soft woods, to give them the right size and shape, as well as a smooth and even surface. The maximum width of the workpiece can reach 318 mm, and the planing depth is limited to 2.5 mm.

The feeding of boards is automatic, the speed is estimated at 8 meters per minute, which is considered a good result for a model with a 1.5 W motor. The motor is protected against overload and is able to work for a long time without a mandatory shutdown.

The model is equipped with comfortable carrying handles, a rigid, stable design and rubber layers to reduce vibration at start-up. To work with wood, two sharp knives made of high-speed steel are used. The table has extensions with rollers that support the workpiece at the entry and exit, and the same upper rollers return it to the table for a second processing cycle. Note that the table has a perfectly smooth table surface so that the workpiece slides over it with minimal friction.

Main characteristics:

- Length / width of the table, mm - 320/285.

- The maximum width / depth of the workpiece, mm - 318 / 2.5.

- Feed rate, m / min - 8.

- Power consumption, kW - 1.5.

- Number of knives, pcs - 2.

- Shaft speed, rpm - 9000.

- Machine weight, kg - 32.

- two diameters of the exhaust fitting, 40 and 50 mm;

- quality performance;

- convenient handles for transportation;

- reliable engine protection.

- Sometimes it can be difficult to find replacement knives.

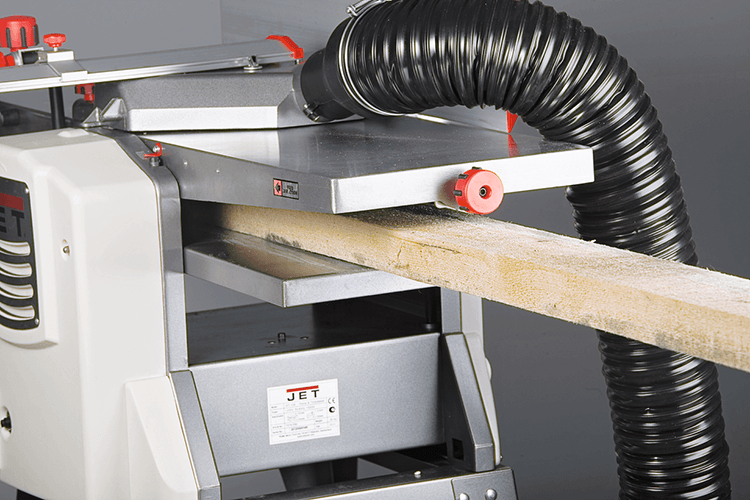

2. JET JWP-12 1.8 kW

|

Expert assessment: ? 9.7 / 10 |

| Owner Review | |

| In general, Jet JWP-12 is a pretty good machine. It is relatively small, but at the same time fast and, so to speak, hardy - it is not afraid of long work. The assembly is excellent, strong and reliable. True, it was not without its drawbacks. Chief among them are native knives. The very first knot - and chips appeared on them. I also had to independently increase the length of the tables, especially at the exit. As a result, I can recommend, but be prepared for the fact that the machine will have to be upgraded a bit for work. |

A popular portable machine for small jobs. It has a good balance between the power of a light commutator-type motor, high shaft speed for planing and a good speed of automatic feeding of workpieces. The model has a well-thought-out chip removal system, folding tables are made with high quality and equipped with longitudinal rollers.

Also, the machine is equipped with a good protective system, consisting of a “claw” protection capable of catching the workpiece during a reverse impact, and a thermal relay unit that prevents the engine from overheating, but has a forced on button.

The machine is suitable for work that requires high precision, however, the sinuses of the machine have to be regularly cleaned of chips, which is why it is not suitable for professional use.

Main characteristics:

- Length / width of the table, mm - 295/318.

- The maximum width / depth of the workpiece, mm - 318 / 2.5.

- Feed rate, m / min - 7.

- Power consumption, kW - 1.8.

- Number of knives, pcs - 2.

- Shaft speed, rpm - 9000.

- Machine weight, kg - 27.

- mobile, compact;

- high-precision result of work;

- good power;

- quality assembly.

- weak native knives, quickly fail.

3. DeWALT DW733 1.8 kW

|

Expert assessment: ? 9.5 / 10 |

| Owner Review | |

| This is, of course, a reliable and durable thickness gauge, which cannot be compared with any of the cheaper Chinese ones. The only thing is that the plastic slider, which acts as a flat lens that enlarges and stretches the divisions on the ruler, is located at some distance from the scale. Therefore, the measurement depends on the angle from which you look at this pointer. Naturally, there can be no question of any accuracy here. |

A model that was developed by the company for sale on the foreign market and is intended for professional use.

Equipped with two high-speed cutting blades and has a power of 1.8 kW, the planer block has a rigid lock, which eliminates any movement during work, even if the surface of the workpiece is uneven. Calibration of lumber becomes available thanks to convenient settings and a special planing depth limiter.

When the voltage in the network increases, the power supply is stopped due to the installed automatic disconnector. The bed of this model is cast, the frame is reinforced. Additional tables are securely fixed and allow you to work with long workpieces without marriage, and their feed rate is 8 meters per minute.

Despite the shaft speed of 10,000 revolutions per minute, the engine can withstand heavy loads well and has overheating protection.

Main characteristics:

- Length / width of the table, mm - 520/319.

- The maximum width / depth of the workpiece, mm - 317/2.

- Feed rate, m / min - 8.

- Power consumption, kW - 1.8.

- Number of knives, pcs - 2.

- Shaft speed, rpm - 10000.

- Machine weight, kg - 33.6.

- reinforced frame, reliable assembly;

- accuracy of work performance;

- good factory calibration;

- can operate at high speed autofeed.

- no significant ones were found.

The best wood planers with two knives

1. RedVerg RD-WP330 2 kW

|

Expert assessment: ? 9.8 / 10 |

| Owner Review | |

| If we talk about the pros, I can note that the thickness gauge has a good assembly, it vibrates relatively slightly and works quieter than other analogues, while it also does not heat up. Also, the machine has a handle that is very comfortable in the hand and a good case. However, the machine is heavy. I also didn’t like the nozzles - they get dull quickly, but other models in this price category are even worse. |

Compact planer with two sharp knives and a powerful motor for high speeds and therefore efficient work.

The blades of the knives are made of high quality HSS alloy. The cutting depth can be adjusted by the user by raising or lowering the planing arm. Installed stops that support the board at the entrance and exit allow you to work with boards up to 330 mm wide.

The advantages of this model, users and experts include compact size and low weight, which simplifies the process of transferring and transporting the machine.There is also a simple control system, the machine is ready to work immediately after being taken out of the box, as the model has a good factory calibration.

Well, a drive with a large traction force will allow you to achieve uniform processing and get a perfectly smooth and even surface at the output.

Main characteristics:

- The maximum width / depth of the workpiece, mm - 330/3.

- Feed rate, m / min - 6.

- Power consumption, kW - 2 kW.

- Number of knives, pcs - 2.

- Shaft speed, rpm - 8000.

- Machine weight, kg - 26.

- high-quality factory setting;

- convenient to adjust the cutting depth;

- suitable for large workpieces.

- chips go badly;

- very noisy at work.

2. BELMASH P1800 1.8 kW

|

Expert assessment: ? 9.6 / 10 |

| Owner Review | |

| I bought a good assistant for my dacha - a Belmash P1500 thicknesser. I consider the acquisition very successful and necessary. Since at the sawmill the logs are cut into boards on a band saw and the board turns out to be different in thickness and width. With a woodworking machine during the day, I single-handedly processed 3 cubes of an inch board. Processing was done on both sides. Later I made a lining from the received board, with which I closed the ceiling in a house under construction. |

An improved version of the P1500 thicknesser, which is distinguished by increased engine power and the ability to connect a special chip ejector.

A single-phase collector motor with double insulation is used. There is a current fuse that will turn off the machine during overload. The power switch has a convenient locking cover. To adjust the depth of planing, a handle is used, and the result is visible on the millimeter scale pointer.

There are two knives with double-sided sharpening, if one side becomes dull, then the blade turns over and you can continue to work. To feed the blanks, spring-loaded rollers with a rubber coating are used that do not leave marks on the wood. There are side metal railings with comfortable handles for transporting the machine. The support of the model is cast, with four holes for secure fixation on a table or workbench.

Main characteristics:

- Length / width of the table, mm - 330/240.

- The maximum width / depth of the workpiece, mm - 330 / 2.4.

- Feed rate, m / min - 7.

- Power consumption, kW - 1.8.

- Number of knives, pcs - 2.

- Shaft speed, rpm - 8500.

- Machine weight, kg - 33.

- good performance indicators;

- suitable for professional use;

- there are carrying handles;

- Easy adjustment of cutting depth.

- high noise level;

- it is required to provide a layer for the base to reduce the level of vibration.

Which firm to choose?

When buying a thicknessing machine, experts recommend giving preference to popular manufacturers of workshop tools and equipment.

These brands have proven their reliability, and are also able to offer the buyer a quality service for further maintenance of devices:

- Makita;

- BISON;

- PATRIOT;

- BELMASH;

- DeWALT.

Useful video

How to choose a thicknessing machine for your home workshop: