How to repair washing machines with your own hands: how to find faults and fix them

Knowing the device of the automatic washing machine, it is not difficult to deal with typical breakdowns of equipment from Electrolux or Siemens on your own.

Knowing the device of the automatic washing machine, it is not difficult to deal with typical breakdowns of equipment from Electrolux or Siemens on your own.

The most important thing in this task is a correctly performed diagnosis, with which you can establish what caused the malfunction.

By the way, even complex repairs of equipment from Vestel or Candy are quite realistic to perform on your own.

Components for washing machines are relatively inexpensive, and all you need from the tool is a couple of screwdrivers and box wrenches.

Content

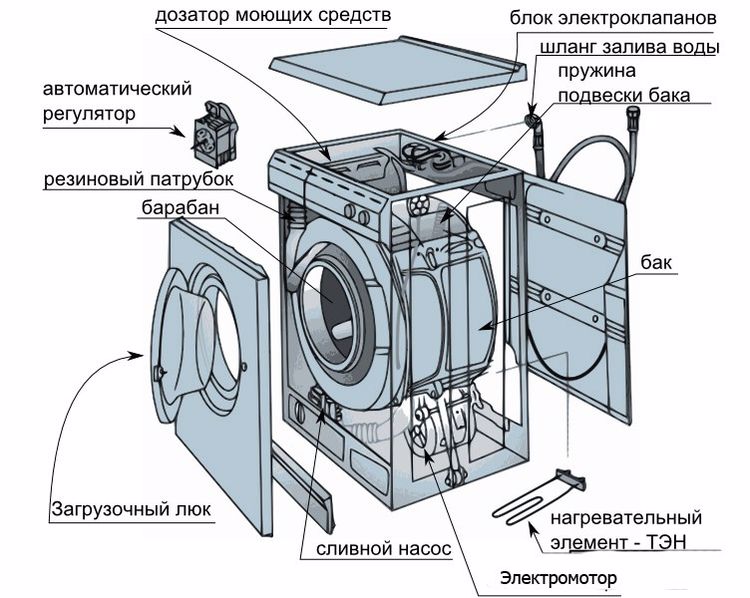

Washing machine device

The basic principle of operation of a washing machine, even LG, even Zanussi, is as follows:

- There is a drum inside. It rotates with the help of an electric motor, which is connected to it by a belt. The drum is encased in a hermetically sealed ABS plastic housing with a bearing pressed into its base.

- The speed of rotation of the electric motor (as well as its direction) is controlled by a digital block. This is a kind of mini-computer in which all modes of operation of the washing machine are programmed.

- The set of water is carried out through a special electric valve. There is no pump for this. Therefore, the washing machine works properly only if a constant pressure is maintained in the water supply. With a weak set, water intake is impossible.

- Water is drained using a pump.

- The drum is held on special shock absorbers. It is due to them that excessive vibration is damped at high speeds of the electric motor.

- Water after the intake is heated using a heating element - heating element.

- Also in the washing machine there is a set of sensors. With their help, the water temperature, the level of the intake, the tightness of the hatch (door) are controlled.

Accordingly, technically, the washing process is performed as follows:

- the user loads laundry into the drum, selects the washing program through the control panel (it is directly connected to the digital unit);

- the washing machine checks if the door is closed, after that the water intake starts;

- the electric motor turns on, the drum rotates according to the program set by the control unit;

- after washing, rinsing and spinning, the pump starts pumping dirty water into the sewer.

Self-replacement of parts

Most often, users of equipment of popular brands have to deal with failure:

- TEN. Responsible for heating water. It is located behind the back wall of the washing machine at the bottom (“inserted” into the drum). Estimated service life is 5 years.

- Drive belt. It is also located behind the rear wall, connects the electric motor and the drum.

- Hoses. They are located outside, but in order to remove them, you will have to partially disassemble the washing machine.

Heating element replacement

To replace the heating element, you must:

- Remove the back wall of the washing machine.

- Unscrew the 3 screws securing the heating element. One of them holds the temperature sensor - it must be carefully removed, cleaned of traces of scale (if any). Also disconnect the wires connected to the heater terminals.

- Pull out the heating element. You can use pliers for this. You will have to apply force, since in most cases the heating element will be fairly covered with a layer of scale.

- Install a compatible new heating element. Also put the temperature sensor in place, connect the wires.

- Check the operation of the heating element. It is enough to turn on the wash in hot water. How to understand that the heating is working properly? Just touch the sunroof with your palm. Another option is to measure the current consumption of the washing machine. When the heating element is on, it will be over 1.5 - 2 kW (without heating, the washing machine, as a rule, consumes less than 500 - 700 W).

Drive Belt Replacement

It is believed that the belt needs to be changed if, when pressed on it, it bends by more than 3 centimeters. This means that it is highly stretched, so it can slip during operation.

Replacing the drive belt is as follows:

- Remove the back wall of the washing machine.

- Remove the belt from the drum pulley. If this fails, then you will need to unscrew the electric motor and move it to the side to loosen the tension.

- Remove the belt from the engine pulley.

- Install new belt in reverse order.

- Install the electric motor back into place.

After - check the performance. It is recommended to start the washing machine and turn on the spin cycle at maximum speed. If the belt slips, a characteristic "whistling" will be heard.

Hose replacement

The washing machine does not need to be disassembled to replace the water inlet hose.

Step by step it is done like this:

- Shut off the water supply. Disconnect the hose from the stopcock.

- Unscrew the water intake hose from the inlet coupling.

- Check for rubber seals. If necessary, clean the mesh filter (protects only large fractions of debris from entering the inside of the drum).

- Install new hose.

But to replace the drain hose, you will need to remove the back wall of the washing machine, since it is attached directly to the suction pump. The procedure is as follows:

- Remove the back wall of the washing machine.

- Find a suction pump. In most cases, it is located at the bottom left, can be covered with a shielding insert.

- Unscrew the drain hose clamp, disconnect it from the pump nozzle.

- Install new hose, tighten with clamp.

After 1 - 2 washing cycles, it is imperative to check whether water is oozing out at the point where the drain hose is attached.

Eliminate noise from the washing machine

Third-party noise during the operation of the washing machine machine occurs in the following cases:

- Drum drive bearing wear. One of the most difficult breakdowns, as you will need to completely disassemble the washing machine.

- Deterioration of the rotor of an electric motor.

- A foreign object has entered the drum. Most often these are buttons, metal elements of fasteners.

Bearing replacement

Replacing the drum drive bearing should only be done if one has experience in such repairs.

The step-by-step process on the example of a Samsung machine is as follows:

- Remove the back and top walls of the washing machine.

- Remove the engine, drive belt, heater.

- Disconnect shock absorbers. In this case, the drum must be held, so the procedure should be carried out together.Or put some kind of dressing under the sealed plastic case.

- Remove the sealing collar (front, behind the door). Most often, this will also require removing the hatch.

- Pull out the drum in a plastic sealed case.

- Remove plastic housing. And this is where difficulties can arise, since most washing machines have it sealed from the factory. That is, it has to be cut with a grinder. In other models, it is enough to unwind the parts of the box, and then disconnect them (in place of the seam they are treated with sealant, so you have to apply force).

- A bearing is pressed into the base of the plastic housing - it is this that needs to be replaced. Most often it is necessary to knock out with a hammer.

- Install new bearing. Put on the drum. As a rule, there are marks on which this is done (or protruding grooves, so the bearing cannot be installed incorrectly).

- Assemble the plastic drum box. Be sure to also apply a water-resistant sealant that is resistant to high temperatures along the seam. Most use automotive (for cylinder block gaskets).

- Install the drum in place, assemble the washing machine in reverse order.

Engine rotor wear

You can also repair an electric motor yourself, but only if there is a problem with the brushes. In such cases, as a rule, spinning does not work normally (rotation speed is too low).

Therefore, the recommended repair option is to replace the engine, which is performed as follows:

- Remove the back wall of the washing machine.

- Disconnect the power cable from the electric motor, as well as the control connector (sometimes they are connected through a single port).

- Unscrew the engine.It is attached in most cases to special metal brackets with screws.

- Remove drive belt.

- Install the new engine in place, put a belt on its pulley.

- Connect the power cable and control connector.

- Check operation (start washing or spinning).

Foreign objects entering the drum

It will be possible to get third-party objects only if they are metal. To do this, you can use an ordinary magnet.

If it is not possible to remove the object in this way, for example, if the Ariston or ARDO washing machine was converted into a removable one, then the drum will need to be completely disassembled.

Replacement of electronic modules

If the control unit is faulty, then the only option to repair it is a complete replacement.

It is performed according to the following algorithm:

- Remove the back and top wall. Behind them, as a rule, there is a plastic insert (fastened with plastic latches).

- The control unit is located in front (immediately behind the button block).

- Loosen the retaining screws.

- It is also recommended to take a picture of how all the connectors are connected.

- In some models, you also need to disconnect the control panel buttons first.

- Remove digital block. Install new one in reverse order.

Replacing the door and detergent tray

The replacement of the hatch, as a rule, is carried out if its glass has been broken or the fastening of the hinges has been damaged.

The replacement process is as follows:

- Open door.

- The hinges are attached on the left. It is enough to unscrew 3 - 4 screws.

- Remove door.

- Install new.

- Check assembly for tightness.

Tray replacement

How exactly the tray is removed should be specified in the technical instructions, since the process may vary in different models of Veko, Atlant, Whirlpool and other washing machines. In most cases, it is enough to open the compartment, press the special plastic clip and pull the tray towards you.

It should also be noted that in new trays there may be transport films at the points of connection with the nozzle of the electric valve (through which water is supplied to flush the detergent). They must first be removed.

Safety rules for the repair of household appliances

When performing any repair of the washing machine, the following rules should be followed:

- Be sure to de-energize the equipment first. That is, disconnect from the mains. Further, it is recommended to wait 1 - 2 hours and only after that proceed with the repair. This is necessary for the self-discharge of the capacitors inside (as a rule, there are near the electric motor, as well as on the control board).

- When carrying out repairs, be sure to use grounding. The best option is to use an antistatic wrist strap. This is especially important when repairing the control unit. Even a slight static voltage can damage it.

- Be sure to connect the washing machine only through the machine (RCD) after the repair. This will protect it from damage in the event of a short circuit (for example, if the electric motor was installed incorrectly or the control connector is defective).

Fault Prevention

To extend the life of your washing machine, we recommend following these tips:

- Open the door after every wash. This will prevent moisture from accumulating inside.After all, it is precisely because of it that the control unit most often fails, since oxides form on the board.

- Clean the detergent drawer regularly. Manufacturers recommend doing this after every wash. Otherwise, abrasive components from the washing powder, as well as scale, will accumulate there. And all this sooner or later will fall into the drum. Also, such particles often “stick” to the heater, which causes it to overheat and subsequently fail.

- Make sure that there are never kinks in the hoses. Gaskets are recommended to be changed every 12 months.

- Clean the mesh filter regularly. This is especially important for those who are connected to the city water supply. Indeed, during maintenance, water pipes are often flushed. And debris, along with rust, can get inside the washing machine.

- Adjust the washing machine so that it is level on the floor. You should use the building level. It will also protect against excessive vibration.

- If the washing machine vibrates strongly during washing or spinning, use a special anti-vibration mat or nozzles on the legs. These are sold in almost all plumbing stores. The key is to have a stable platform. If the house has wooden floors, then you will have to perform local concrete pouring.

- Select the correct washing mode. Do not always use maximum water heating. From this, firstly, a much greater consumption of electricity, and secondly, the operational life of the heating element is significantly reduced.

In total, it is quite possible to repair a washing machine with your own hands and replace failed components. If any difficulties arise, you can always contact the authorized service center of the manufacturer.

You also need to remember that if you disassemble the washing machine yourself, the terms of warranty service will be canceled. That is, after that, repairs will have to be carried out only at their own expense.

Useful video

From the video you will learn how to fix the washing machine and what to look for: